PROPERTIES

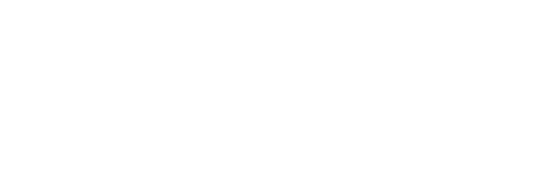

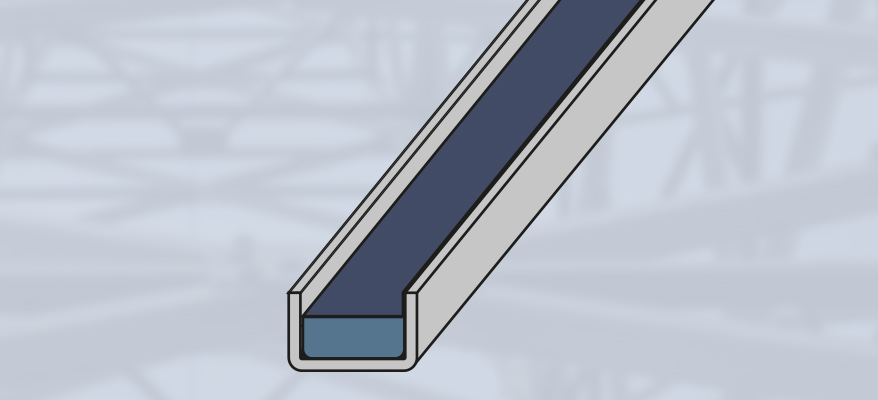

Our CFRP sandwich rods have a circular grinded foam core covered with one or more fiber composite layers.

We manufacture our lightweight rods in two variants: The most commonly used variant A has a layer of unidirectional C-fibers on top of the lightweight foam core, surrounded by a thin glass fiber mesh. This rod has a high specific bending stiffness and also high tensile and compressive strengths. The thin glass fiber mesh on the surface serves to protect the rod and at the same time, by “whitening”, provides damage detection for damage that may occur subsequently due to impact.

If the bar has to have a high torsional stiffness, C-fiber fabric with a fiber orientation of ±45° is added (variant B). This can be done either by covering the foam core rod with a C-fiber tube before production, or by covering the entire rod with a C-fiber tube fabric again in a further process step. Which version is used in each individual case depends on the requirements for the rod.

Another way of adapting CFRP sandwich rods to the particular applications is to use suitable fibers whose properties range from very flexible to highly rigid and high-strength. In particular, C-pitch fibers are used to achieve extremely high stiffness.

Our stock now comprises around 60 different types of CFRP rods, which can also be purchased in very small quantities. Even from a quantity of about 20 to 30 meters, the production of customized rods is economically feasible.

Typical Characteristics/Unidirectional

| Diameter: | 8mm .. 120mm |

| Wall thickness: | 8mm .. 120mm |

| Maximum length: | 28m (uninterrupted) |

| Properties of the rod wall (PAN fiber) | |

|---|---|

| Young’s Modulus: | 170GPa .. 190GPa |

| Tensile strength: | 2000MPa |

| Compressive strength: | 700MPa |

| Coefficient of thermal expansion: | -0,2*10-6 .. -0,3*10-6/°K |

| Properties of the rod wall (pitch fiber) | |

|---|---|

| Young’s Modulus: | 270GPa .. >300GPa |

| Tensile strength: | 1000MPa |

| Compressive strength: | 300MPa |

| Coefficient of thermal expansion: | -1,0*10-6 .. -1,2*10-6/°K |